Value Added Services

AluFab offers a full range of services to help your project move quickly and smoothly.

From project design and 3D drafting to full onsite installation, AluFab can do as much or as little as you need! Contact Us to discuss your aluminum fabrication solution.

Design & Engineering

The first step in any project is an idea, and turning that idea into a design can often be difficult. AluFab has experienced engineers that have designed, constructed, and built structures using the structural T- slotted extrusion that AluFab offers. Our engineers can help you turn your concept into a technical drawing whether that concept is just an idea, a sketch, a picture, or an outdated drawing. Our team can make recommendations on which profile to use, how to fasten or assemble your structure, where to add support and how, and much more. If you have an existing drawing that you are not sure how to interpret or what to make of it, pass it along to our team of engineers and we will turn it into an up to date, clear and concise technical drawing. Learn more about Alufab’s Custom Design & Engineering.

Machining

Often when working with t-slotted aluminum extrusion, machining is required to allow the extrusion to be put together with a desired fastener. Luckily, AluFab has the full capability to provide any and all machining that may be required by your project. Whether its extrusion, panels, or special accessories AluFab’s machining team can do it all so that your project arrives exactly how you need it. Some common machining operations that are used with t-slotted aluminum extrusion include:

Access Holes/Taps

Access holes are a small drill hole that goes through the t-slot of a piece of aluminum extrusion. The purpose of an access hole is to reach your tool through and tighten something on the other side, often the head of a bolt that is connected to another piece of extrusion as an end fastener. An end fastener is partially threaded into the end of one piece of extrusion, and then slides in the t-slot of another piece. When you reach an Allen wrench through the access hole and tighten the bolt, the head of the screw grip the t-slot and fastens the two piece of extrusion together. In addition to the access holes AluFab also has the capability to tap the end of extrusion profiles to a number of different thread sizes. Threaded holes along the length of the extrusion are also available.

Counterbores

One of the most common fasteners used with AluFab’s t-slotted aluminum extrusion is anchor fasteners. Customers love using anchor fasteners for their high strength properties while remaining one of our lowest-priced fastening options. In order to use anchor fasteners, a counterbore is drilled into the end of one piece of extrusion to fit the anchor fastener cam.

Miter Cuts

Another common type of aluminum extrusion support is a 45 degree support, which requires a piece of aluminum extrusion to be cut at a 45 degree angle on both sides. Then, an access hole is drilled through the extrusion at an angle so that the angled end will line up with the t-slot of another piece, and a bolt can be threaded through to connect the pieces and support your structure.

Panel Cutting/Notching

AluFab also possesses the full capability to cut panels to size, no matter the material. Depending on how your panel is going to fit within your structure, the corners may need to be notched to go around an extrusion end or an existing fastener. That is no problem, because AluFab can handle that as well!

Custom Machining

If any other machining is required within your project, we welcome you to ask if our team is equipped to handle it!

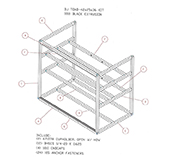

Assembly Instructions

If you elect to have your project delivered unassembled as a kit, AluFab will still go to lengths to make it easy on you! Upon request a reference drawing can be included, that labels each piece within your structure. Those labels will correspond with the aluminum extrusion you receive, with all like pieces wrapped together and labeled. If a reference drawing is not requested, your piece will still be labeled according to length so that you can easily identify them without having to take the time to measure.

Throughout the assembly process, our team is always standing by to answer questions, provide helpful videos, or recommend assembly order or methods. Give us a call or send us an email and assembly will be easier than you ever could have imagined!

On-site Design, Engineering, Installation

Aluminum extrusion has been using in the manufacturing industry for years as guard panels, perimeter guards, machine enclosures, and workstations. Often those projects are specific to the layout of a given plant or facility, and that’s where AluFab can make it easy on you! Our team of engineers is ready to come to your facility for a site visit to look at an area that needs to be guarded, measure out any dimensions or specifications that will be involved, or give recommendations on types and layout of guarding.

Technical drawings can then be provided according to dimensions specific to your facility. That allows the customer to incorporate our guard drawings directly into their plant or machine drawings, making sure everything will line up and function as intended. If you have a drawing of an area, machine, or cell that needs to be guarded, simply let AluFab’s engineers take a look and we will draw and design the machine guarding around your plans and specific to your requirements.

Finally, if your employees are unfamiliar with aluminum extrusion, or do not have the time to install a full set of guard panels, ask AluFab about their install team. AluFab has an experienced and knowledgeable install team ready to come to your facility and take over the installation process. Guard panels and enclosures will be the last thing you have to worry about in your project when working with AluFab’s installation team.